Camshaft and crankshaft sensors

Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly.

Camshaft and crankshaft sensors

How they work

These two types of sensor help the electrical control unit (ECU) calculate the position of two key parts of the engine: the camshaft and the crankshaft.

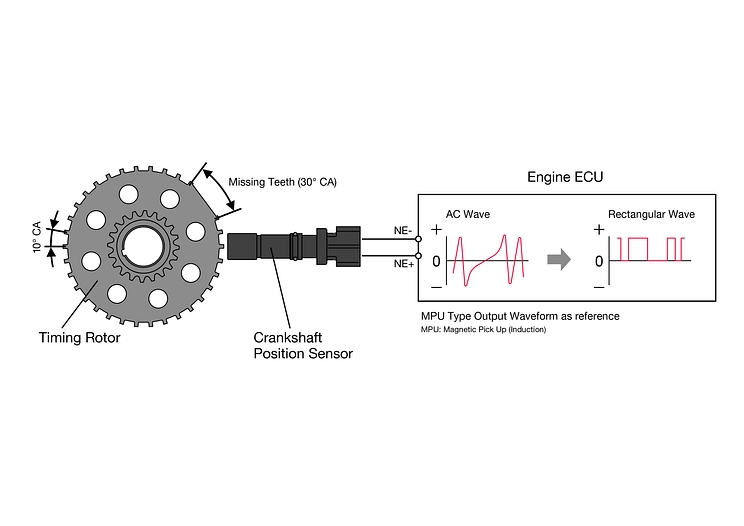

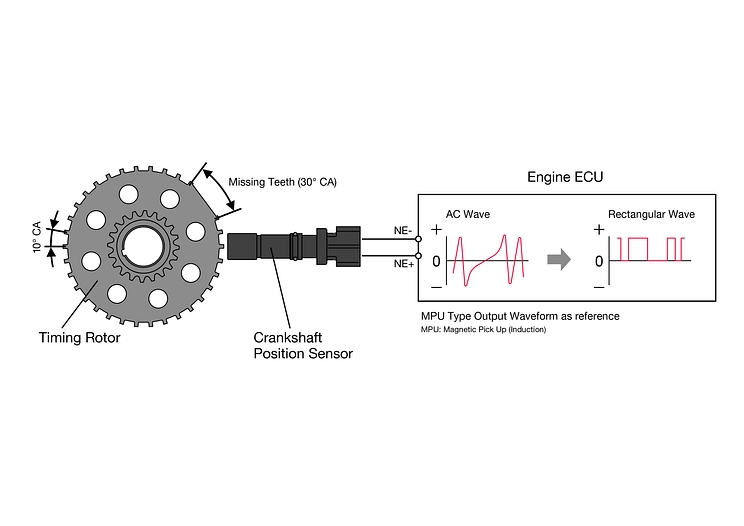

The crankshaft position sensor is attached to the engine block facing the timing rotor on the crankshaft. It counts the number of teeth on the crankshaft that have passed the sensor, sending this value to the ECU which can then work out where the crankshaft is on its 360-degree rotation. The rate of positional change is used to calculate the engine’s rotational speed.

The camshaft position sensor is mounted near the cylinder head, opposite the timing rotor attached to the engine camshaft. It monitors the changing magnetic resistance from the moving magnetic field of the timing rotor; this information is used by the ECU to calculate the camshaft angle and to recognize which cylinder is firing.

Together, these components ensure the engine parts remain ‘in time’ and the engine operates smoothly and efficiently. With both Magnetic Resistant Element (MRE) type and Magnetic Pick-Up (MPU) type sensors available, DENSO offers a comprehensive range of OE-quality sensors to the aftermarket.

Features and benefits

-

Variety of sizes and designs available, across inductive and semiconductor types.

-

Excellent reliability, with simple and problem-free connections and high temperature resistance.

-

Guaranteed first-time fit and superior performance.

-

The DENSO name is associated with high quality and low return rates.

Types and characteristics

Camshaft and crankshaft sensors types

Characteristics

MRE-type sensors use DENSO’s own magnetic circuit design, with a one-chip integrated model. MPU-type sensors are available as either direct-connection or lead-wire sensors, maximising car parc coverage.

Installation and fault finding

Correct installation, maintenance and monitoring of DENSO camshaft and crankshaft sensors will keep them operating to their fullest potential, powering efficient engine performance.

Installation

Take care – camshaft and crankshaft sensors are a delicate piece of hardware that can be damaged when installing. Do not allow ingress of moisture, chemicals or other foreign materials; do not place sensors in areas where excess static discharge is continuously applied; and do not place sensor tips close to each other or to a magnet.

Disconnect the connector and wiring if it exists. Remove the screw(s). Remove the sensor.

Install the new sensor and screw(s) according to the tightening torque value specified by the vehicle manufacturer. Connect the connector and sensor wiring if needed. Turn the engine on and check that the system works properly.

Fault finding

Scratches on the magnetic surface of the sensor

Foreign material on the magnetic surface of the sensor

Exposure to significant high heat

Wear and tear in the sensor wiring

Stalling after starting, or infrequently during vehicle operation

The vehicle accelerates inconsistently

The vehicle occasionally loses power or misfires

Intermittent starting or no start at all

The engine light turns on

During cranking, use the scan tool oscilloscope function to inspect the sensor’s voltage waveform. If there is a normal waveform, inspect for faulty ECU, open or short circuit problems in wiring. If there is no waveform, inspect for faulty sensor.

Replace the sensor, making sure the timing rotor and sprocket do not touch the magnetic surface of the sensor (select correct thickness shim and/or assure proper clearance).